Effect of Sintering Time on the Densification of Pure Nano-Sized BaTiO3

Researcher: Mr. Md. Muktadir Billah

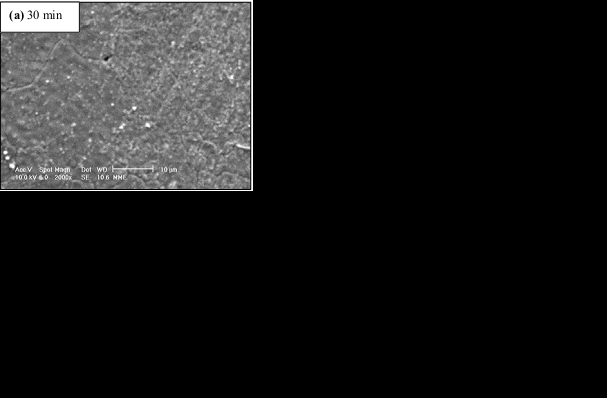

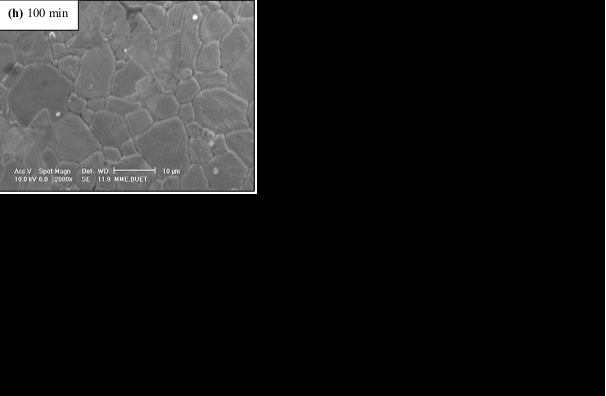

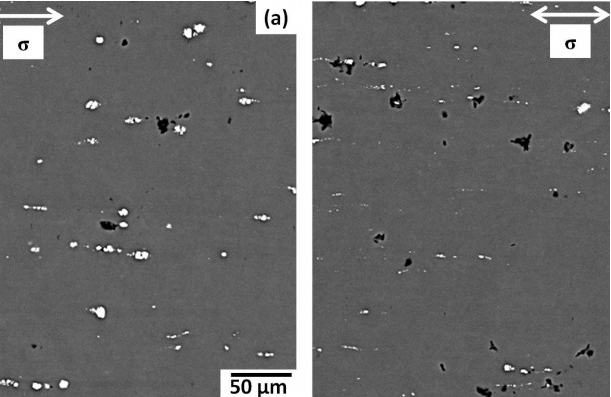

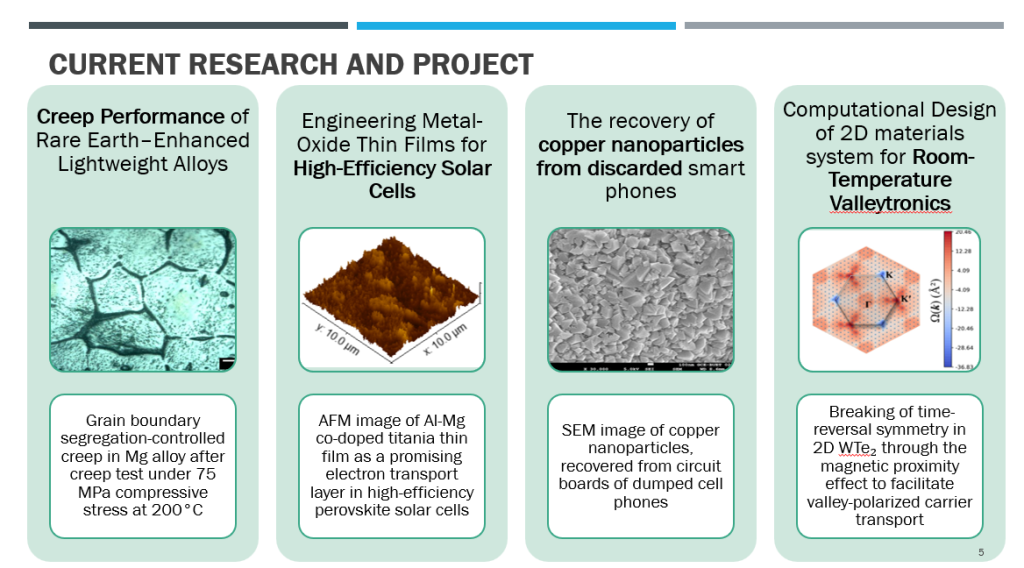

Sintering of nano-sized pure BaTiO3 was carried out at 12200C between 30 to120 minutes. From the density vs sintering time curve, three stages of densification were identified followed by a stage of de-densification, based on the rate of densification. In the first stage, very high rate of densification was observed up to the sintering time of 40 minutes. In the second stage, the rate of densification started to decrease with increase in sintering time and this trend continued up to 90 minutes. In the third stage, the rate of densification was really low which continued up to the sintering time of 110 minutes. Finally, in the fourth stage, the rate of densification showed a negative trend and the overall density was lowered due to de-densification.

Caption: SEM micrograph of pure BaTiO3 sintered at 1220C for sintering time ranging from 30-120 minutes.

Effect of Reinforcements on the Structure and Properties of Lead Free Tin Zinc Alloys

Researcher: Mr. Md. Muktadir Billah

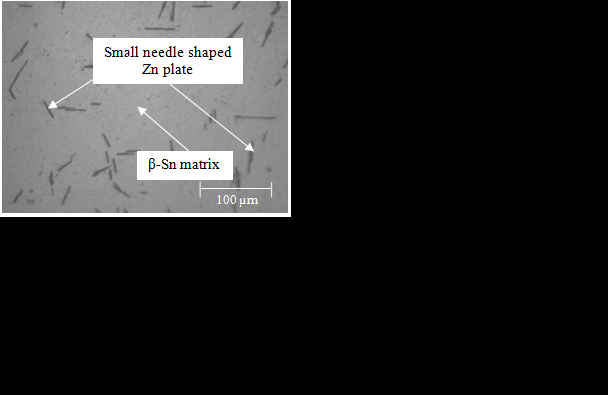

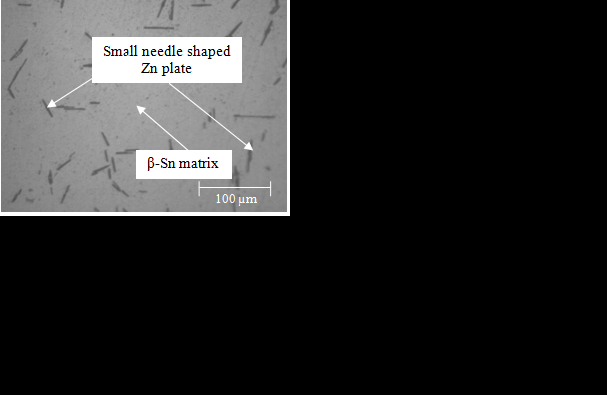

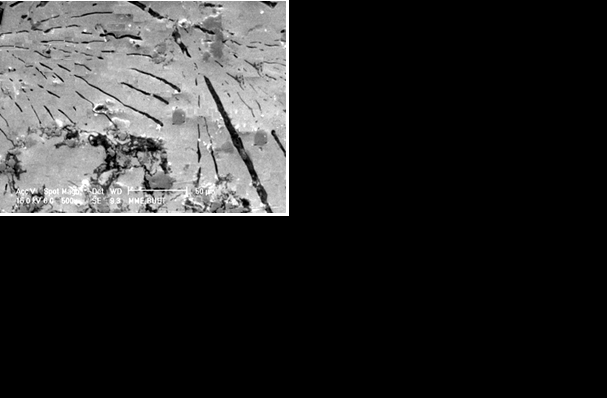

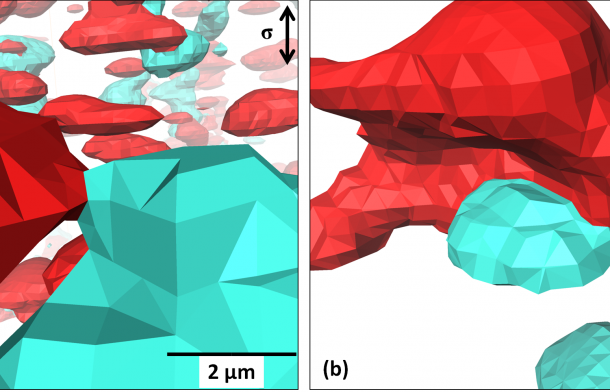

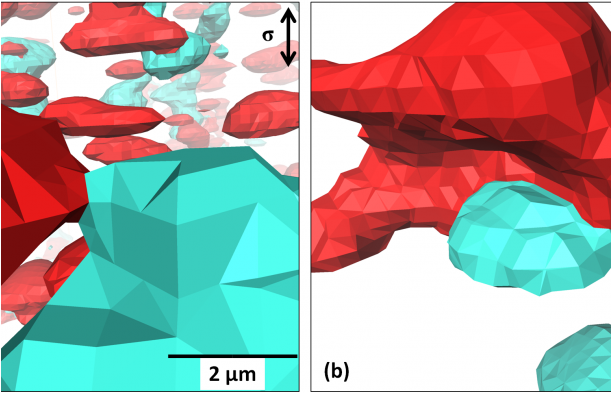

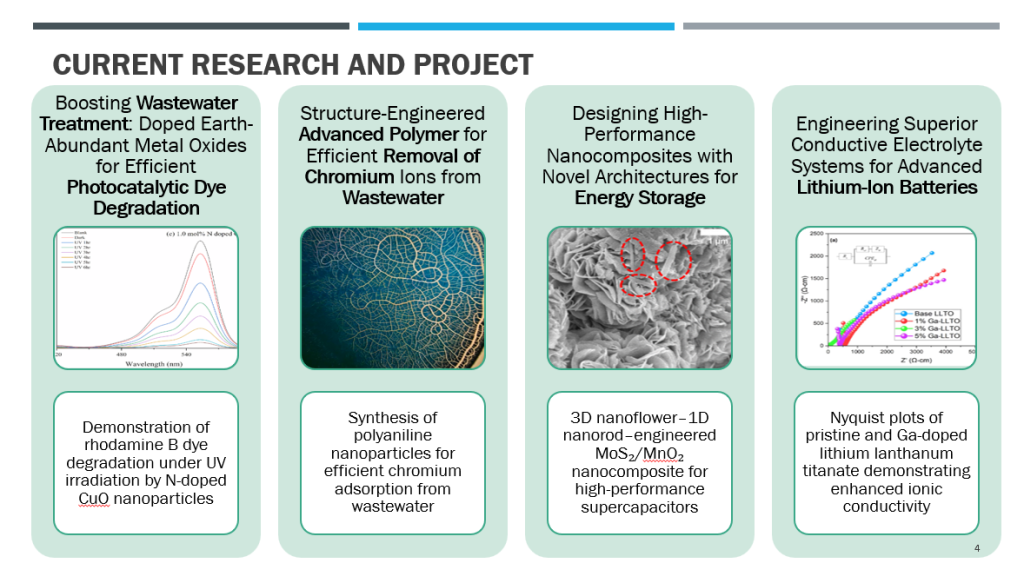

In the study 3.0 weight percent Bi was added in the Sn-9Zn eutectic solder alloy to investigate the effect of Bi on the microstructure, mechanical and thermal properties of Sn-9Zn alloys. Effect of three different weight percentages of micron size Ni powder addition viz. 0.25, 0.5 and 1, on the microstructure, mechanical and thermal properties of both the Sn-9Zn and Sn-8Zn-3Bi alloy systems were investigated. Characterization was performed using DTA, SEM, EDX, XRD and different mechanical properties were measured. The results indicated that Bi addition improved mechanical properties and lowered melting point while increasing solidification range of Sn-9Zn alloy. Melting temperature and solidification range were increased with Ni addition in both Sn-9Zn and Sn-8Zn-3Bi alloy. Addition of small amount of Ni (0.25%) refined the Zn needles and caused Zn precipitation in the β-Sn matrix. Ni addition initially increased hardness and ultimate tensile strength. Optimum mechanical properties were found for Sn-9Zn-0.25Ni and Sn-8Zn-3Bi-0.5Ni alloys.

Figure Captions:

1. Sn-9Zn alloy (Optical) 2. Sn-9Zn alloy (SEM) 3. Sn-9Zn-0.25Ni alloy (Optical) 4. Sn-9Zn-0.25Ni alloy (SEM) 5. Sn-8Zn-3Bi alloy (Optical) 6. Sn-8Zn-3Bi alloy (SEM) 7. Sn-8Zn-3Bi-0.5Ni alloy (Optical) 8. Sn-8Zn-3Bi-0.5Ni alloy (SEM)